Selective soldering plays a key role in the production of contract electronics for various reasons:

- High accuracy and control

- Savings on the materials used

- Precise plotting of the soldering paste to some layers, so-called soldering of multi-layer PCBs

- High efficiency

- Reduction of errors

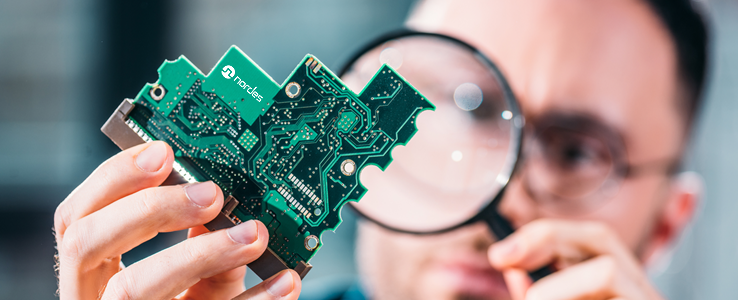

Focusing on the development and the complexity of our services we purchased a new machine ERSA VERSAFLOW 4/55 which is an advanced equipment for automatic selective soldering. The accuracy and effectiveness of soldering, as well as a precise system of temperature control and stability, are the key advantages of this machine. ERSA VERSAFLOW 4/55 uses advanced technology that enables precise monitoring and control of the temperature in real time. In that, it is possible to achieve optimal conditions for soldering a variety of electronic components. As a result, the soldered connections are of very high quality.

More information below: Nordes focuses on the accuracy of selective soldering in EMS production. | Nordes EMS