With the current rapid development of technology, electronics manufacturing is one of the most important industry sectors. To become successful, electronics manufacturing companies need to focus on quality, efficiency, and pace of production. These are the reasons for which Electronics Manufacturing Services (EMS), also called Contract Electronics Manufacturing (CEM), have become an inherent part of modern industry.

What is Contract Electronics Manufacturing?

Professional Contract Electronics Manufacturing focuses on cooperation between companies where one has an idea for a product or its design and the other (EMS) becomes responsible for its production. The EMS provider implements, produces, and delivers electronic goods on demand. Currently trending amongst EMS producers is complexity, which focuses on the complete assembly of PCB.

The global EMS market is developing rapidly – almost 7% annually (CAGR), which is evidenced by a forecasted value of 800 billion dollars before 2029. The growth of the EMS market is powered mainly by such industries as telecommunication or medicine.

Why do OEMs choose complex Electronics Manufacturing Services?

OEM (Original Equipment Manufacturers) companies outsource their production to EMS providers for various reasons that may benefit both parties. The most important aspects for which OEM companies choose to cooperate with EMS providers are:

- Technical knowledge and experience – EMS suppliers are experts in the field of electronics manufacturing and assembly. They have the skills that enable them to manage the production cycle well thereby EMS suppliers can provide high-quality products and services for their customers.

- Economies of scale – companies offering EMS usually have developed machine parks and production capabilities that enable them to achieve economies of scale. By manufacturing goods for a variety of customers, EMS suppliers can reduce the production cost and share the savings with their customers.

- Flexibility and adaptation – CEM offers complete flexibility and adaptation concerning the customer’s needs and requests.

- OEM focus on business – by outsourcing production OEM can focus on their other key business factors without the need to invest in production infrastructure.

The most popular CEM services

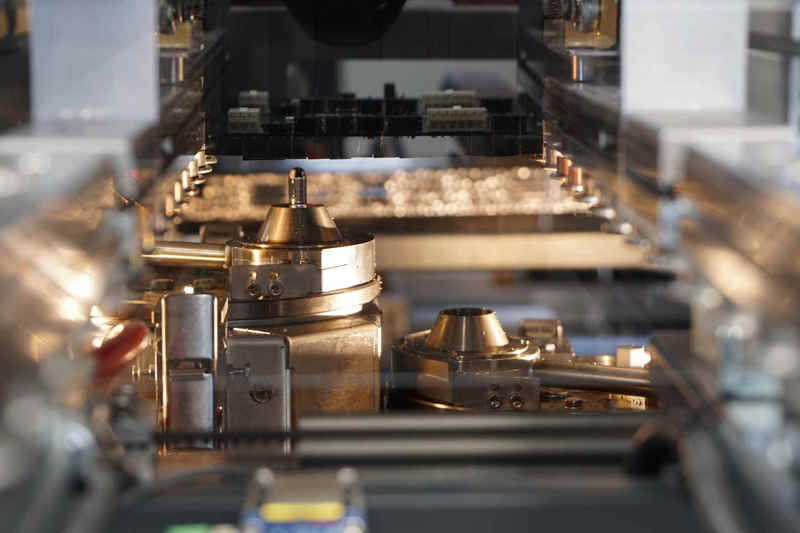

One of the most popular CEM services is PCB assembly (PCBA). Nowadays, the assembly processes can be completed very fast while maintaining the precision of the components’ layout and the high quality of the finished product. Investing in advanced SMT (Surface Mount Technology) assembly lines may be very expensive for OEM companies therefore outsourcing is becoming more and more popular. EMS suppliers can provide complex manufacturing services and ensure efficiency and high-quality electronic solutions.

EMS suppliers offer a variety of services for different industry sectors and companies. Common CEM services are:

- Designing and prototyping

- Surface Mount Assembly (SMT)

- Through-Hole Assembly (THT) – traditional assembly of components through holes in PCB

- Box building (final assembly) and encapsulation of electronics

- Electromechanical assembly including enclosure assembly

- Testing and verification

- Assembly and integration of components

- Managing supply chain

- Adaptation and personalization

- Customer service and after-sales service

- Logistics and distribution

These services enable companies from various sectors to use the advanced infrastructure and technical knowledge of EMS suppliers to effectively manage electronics production, shorten the time-to-market period, and achieve high-quality finished goods.